Everyone should be familiar with paper. Because we can see all kinds of paper products in many scenes in daily life. For example, we are familiar with paper cups, paper bowls, paper plates and fast food boxes. We all know that paper is hygroscopic (readily absorbing moisture) and has low bursting strength. But if you are careful, you will find that these papers have a clear, glossy, smooth touch film on the inside. That is a PE film, which seems to put a magical coat on the paper, giving it the super power of not afraid of water and oil. Let's uncover the mystery of coated paper together!

Contents

1. What is PE?

2. Classification of PE.

3. Distribution of PE production capacity by country.

4. What is PE coated paper? What is it used for?

5, Classification of PE coated paper.

6. Application of PE coated paper.

What is PE?

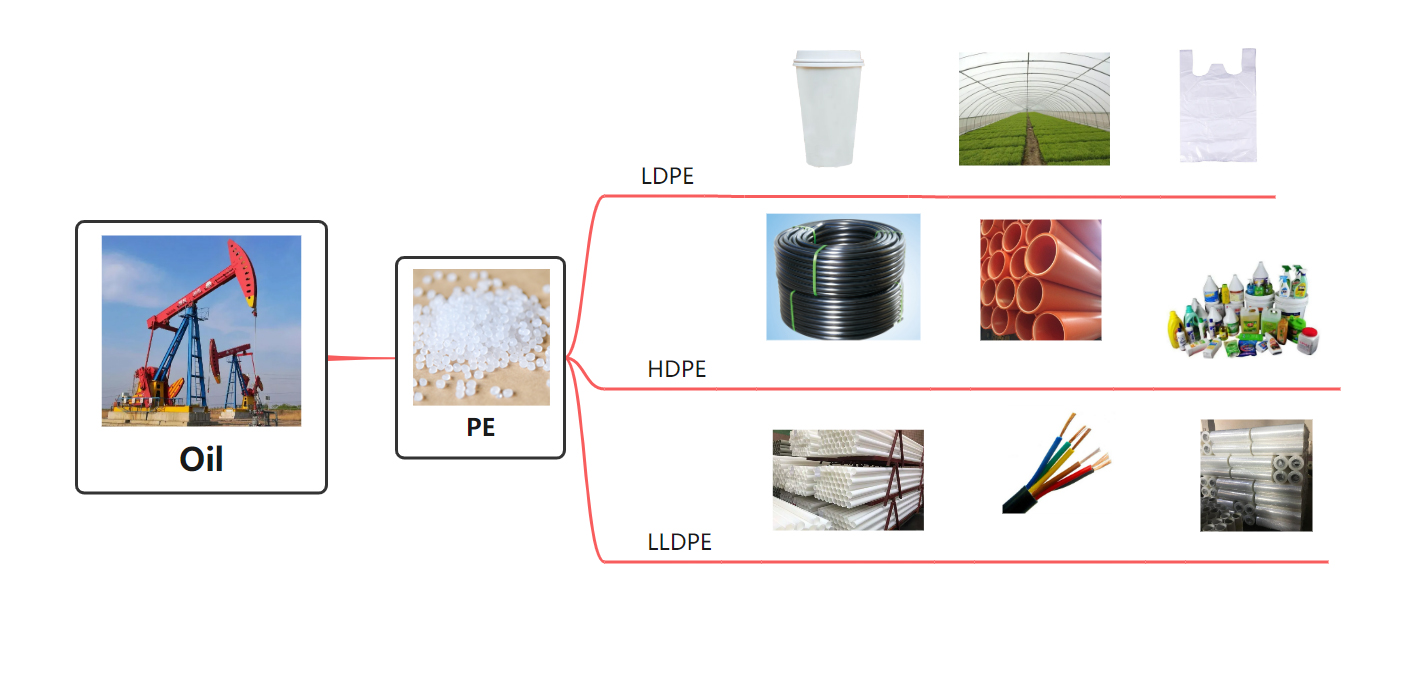

Before understanding PE coated paper, let's talk about its main raw material - polyethylene. Polyethylene is short for PE, which is a thermoplastic resin polymerized from ethylene. The appearance of polyethylene is milky white waxy particles, which are tasteless, odorless, non-toxic and feel like wax. The main feature of polyethylene is cheap, which has excellent cold resistance, chemical stability, electrical insulation and other characteristics. So it has a very wide range of applications. Mainly used in the manufacture of films, packaging materials, containers, pipes, wires and cables, daily necessities, etc. What's more, it can be used as high-frequency insulating materials for televisions, radars, etc. Since its application in 1922, polyethylene has developed into the world's largest synthetic resin and the largest consumption of plastic packaging materials. It occupies a pivotal position in the plastics industry.

Classification of PE

Due to the different polymerization processes of polyethylene, its structure is also different, and the corresponding product properties are also very different. Mainly can be divided into: Low-Density Polyethylene (LDPE), Linear Low Density Polyethylene(LLDPE), High-Density Polyethylene(HDPE).

LDPE: Mainly used for synthetic paper, agricultural film, film for industrial packaging, wire, etc;

LLDPE: Mainly used for wires and cables, pipes, daily necessities, etc;

HDPE: Mainly used for ligatures, ropes, fishing nets, etc.

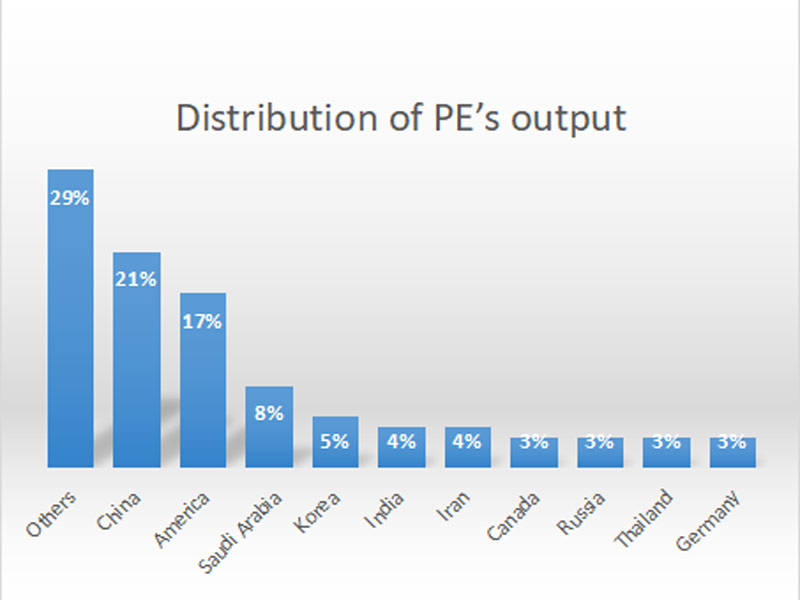

Distribution of PE production capacity by country

As of April 2022, China's PE production capacity has reached about 29.18 million tons, accounting for 21% of the world's total PE production capacity. It can be seen from the data that the global PE production capacity is mainly concentrated in China, the United States and Saudi Arabia. China is currently the country with the largest polyethylene production capacity in the world.

What is PE coated paper?

We have already had a deep understanding of PE above, so what is PE coated paper? Simply put, PE coated paper is a composite material made of paper as the base material and coated with a layer of polyethylene film on the base paper, that is, the plastic particles are coated on the surface of the paper by a casting machine. Paper is easy to get wet, but after being perfectly combined with polyethylene, coated paper can achieve the effects of waterproof, oil-proof and high-temperature resistance.

Classification of PE coated paper

According to the difference between the number of coated film, it can be divided into single-sided PE coated paper, double-sided PEcoated paper, and interlayer PE coated paper.

1. Single-sided PE coated paper

Single-sided PEcoated paper is coated with PE film on one side of the base paper. It is used in hot drinking paper cups, hamburger paper, etc.

2. Double-sided PE coated paper

Double-sided PE coated paper is PE coating on both sides of the base paper. It is used in cold drinking paper cups.

Interlayer coated paper

Sandwich coated paper is to put PE coating between two base papers to synthesize one piece of paper to enhance the flexibility of the paper.

Commonly used in: desiccant packaging, food packaging bags, etc.

According to the different coatings, it can be divided into two types: bright film and sub-film.

Bright film is a transparent double-sided polyethylene film with bright surface and smooth hand. The matte film is a matte polyethylene film with a matte film with a fogged surface.

The sequins have high definition and the printed matter is more colorful. Matte films are more muted in color.

The use of coated paper

Coated paper is closely related to our daily life and has a wide range of uses, mainly used in packaging, food, medical, electronics, hardware, die cutting, etc.

Application scope of coated paper:

Scope of application of coated paper

1. Chemicals: desiccant packaging, mothballs, washing powder, preservatives.

2. Food: noodle bundles, ice cream packaging, milk.

Post time: Nov-16-2022