Food Grade PE Coated Paper In Sheet

Overview

| Product Name | PE coated paper sheet |

| Paper Weight | 150 ~ 350gsm |

| PE Coated Weight | 10 ~ 30gsm |

| Width | Custom manufacturing |

| Coating Side | Single and double side |

| Core Dia | 3 inch , 6 inch |

| Use | Paper cups, paper bowls and food boxes , etc |

| Material | 100% Wood Pulp |

| Feature | Waterproof, greaseproof, resist high-temperature |

| Size | Customer demand |

| Custom Order | Accept |

| MOQ | 5 tons |

| Lead Time | 20-30 days after confirm the deposit |

| FOB Port | China port, such as QINZHOU,GUANGZHOU,SHENZHEN |

PE COATED PAPER SHEET

* Professional manufacturer of PE coated paper.

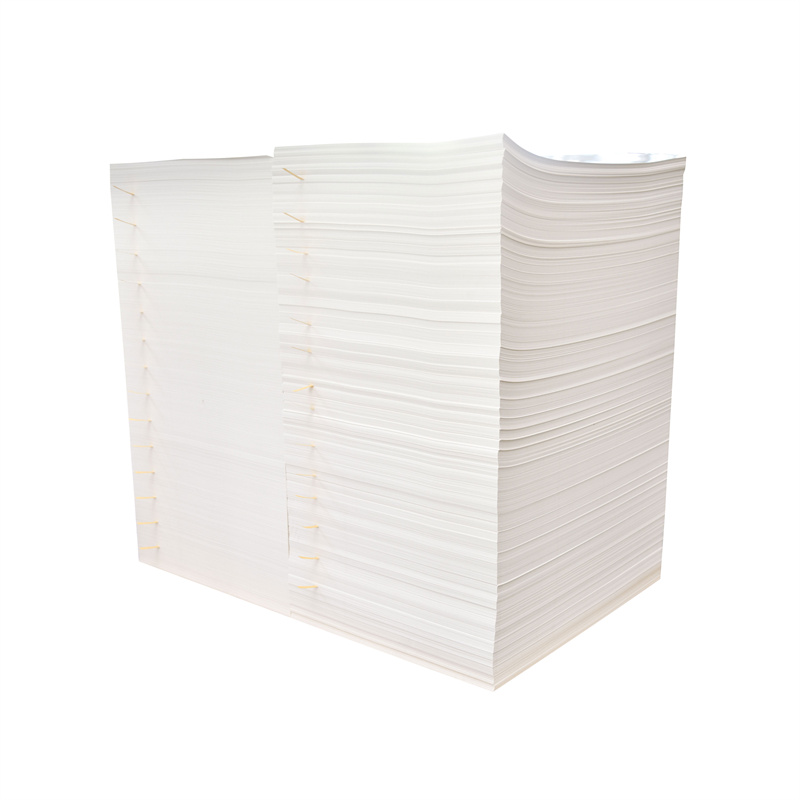

*No impurities,neatly cut at both ends of surface, smooth surface.

PRODUCTION DESCRIPTION

PE COATED PAPER SHEET

Base Paper: 150 ~ 350gsm

PE Weight:10 ~30gsm

Size:Customer demand

Applicability: Offset or flexo printing

Use: Paper cups, paper bowls and food boxes, etc

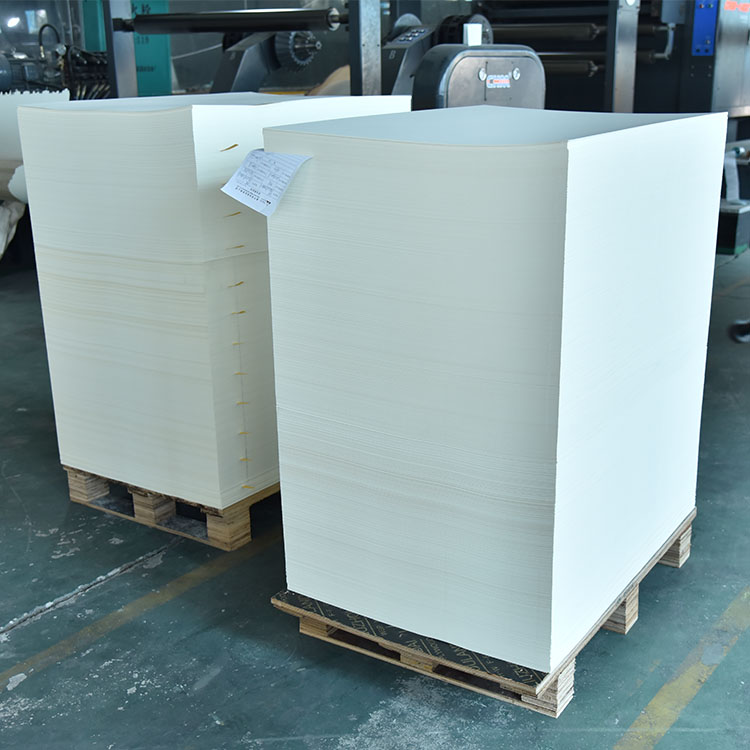

Packaging: Pallet

SHOW DETAILS

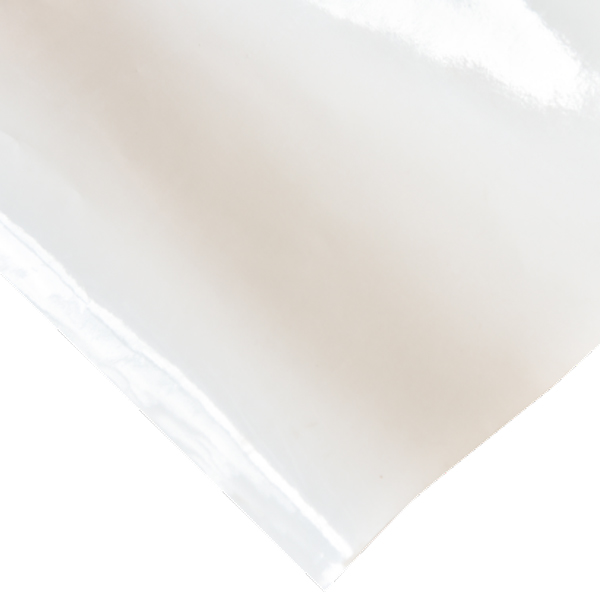

01. Food Grade Materials

1. Materials: Food grade PE materials

2. Base paper :100% Wood Pulp

3. Certified: SGS, Test Report No. Is GZAFF160910888ME

02. Product Feature

1. Good stiffness, smooth surface, high firmness of PE coated layer.

2. PE coating prevent leakage, moisture.

3. Waterproof, greaseproof, resist high-temperature.

03. Products Detail

1. Fast shipping, quality guarantee;

2. Good flexibility

3. Matt lamination and Glossy lamination.

APPLICATIONS

PE coated paper can be widely used to make a variety of products, such as:

1. Paper cup.

2. Paper bowls.

3. Paper bag.

4. Food boxes, etc.

PRODUCTION PROCESSING

1. High-quality bace paper

2. Bace paper material testing

3. PE coating processing

4. PE coating finished

5. QC inspection

6. Packing finished

QUALITY CONTROL

Quality control is one of our very important procedure during the production. PE coating quality control as below.

1. Bace paper testing

2. Coating machine inspection

3. PE coating fastness verification

4. Roll tidy verification

5. Roll weight verification

6. Packing verification

PACKING SOLUTION

1. Wrapped by paper and kraft paper outside:

Paper is strong and it is good to protect the paper sheet l from scratches or damage.

2. PE film wrapped outside:

PE film is for prevent the paper roll from dust and moisture, to keep the paper roll to be dry and clean.

3. Pallet loading:

Pallets makes the paper rolls to be much more easier for loading and unloading.

1. Wrapped by paper

2. Kraft paper wrapped

3. Packed by pallet

WHY CHOOSE US?

16 years manufacturing experience,10 years exporting experience

Our factory covers 15,000 ㎡, there are 200 employees. With more than 16 Years raw materials for paper cup .Our products are exported to 100 countries.The annual output reach to 42000 tons.

Certification system

All products are certified through ISO,SGS . We can provide first-class quality products to you.

High quality base paper

We specially choose high-quality and stable supply ,like APP,ENSO for our based paper. 100% virgin Wood Pulp.

Safe business

Payment methods varied, T/T, L/C, D/P, etc. Our professional team can make your order more easily and safety.

MAIN PRODUCTS

Our products including PE coated jumbo roll, paper cup fan,cup bottom roll, paper in sheet and C1S ivory board, which are widely used in packaging and printing like beverages ,food,pharmaceutical box, high-end cosmetics packaging or whatever packaging the item may be suitable for.